The functioning of every electric rickshaw highly depends on the motor used in them. We understand that electric rickshaws run on battery, however, their long term performance not only depends on battery, speed, or initial pickup. But it also depends on the consistency, durability, and efficiency over thousands of operating hours. When investing in E-Rickshaws, buyers often compare multiple E Rickshaw Motor Manufacturers before making a decision. Yet many overlook the technical and practical factors that truly determine motor life.

Based on our experience in manufacturing motors, we believe the right choice comes down to a few essential considerations that directly impact daily performance and ownership cost. We are sharing some of them in this blog to help you invest in the best E-Rickshaw motor for long-term performance.

Motor Power and Load Compatibility

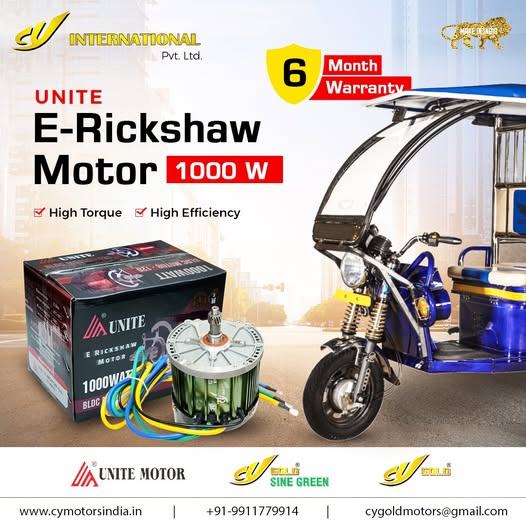

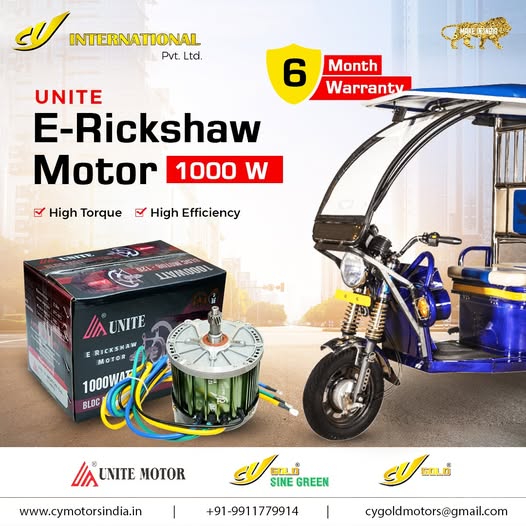

The first step in selecting the right motor is matching power output with real operating conditions. A motor that looks powerful on paper may fail prematurely if it is constantly overloaded or used beyond its rated capacity. We design motors by keeping passenger load, road gradient, and stop and go traffic in mind. When motor power aligns correctly with vehicle usage, heat generation remains controlled and internal components experience less stress. This balance allows the motor to deliver smooth torque while maintaining efficiency over the long term.

Build Quality and Internal Components

Long term performance depends heavily on what is inside the motor. Copper winding quality, insulation grade, and rotor balance all play a decisive role in durability. We emphasize precision manufacturing because even minor inconsistencies can lead to vibration, noise, and faster wear. A well-built motor runs cooler, consumes energy more efficiently, and maintains stable output across seasons. Buyers should always consider how carefully a motor is engineered and assembled. Being one of the trusted E Rickshaw motor manufacturers, we invest in controlled production processes to ensure every unit meets the same performance standard.

Thermal Management and Operating Conditions

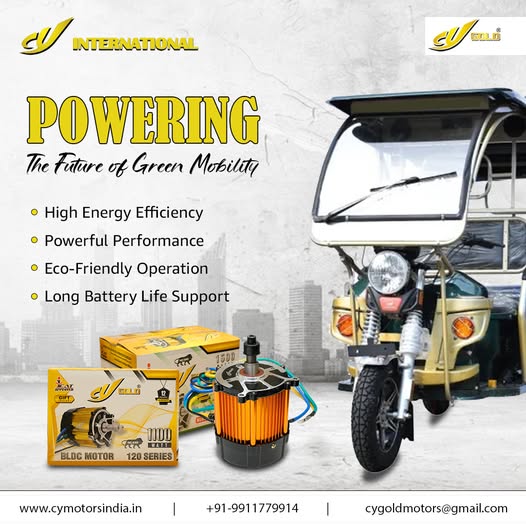

Electric rickshaws operate for extended hours, often in high temperatures and congested routes. Effective thermal management becomes essential for protecting motor life. We design motors with ventilation and heat dissipation in mind so that performance remains steady during long duty cycles. When heat is managed properly, bearings last longer, winding insulation stays intact, and power delivery remains consistent. Motors that ignore this aspect may perform well initially but degrade quickly. Selecting manufacturers who understand real usage conditions makes a clear difference in long term reliability.

Conclusion

Choosing the best motor is about making an informed decision that balances power, build quality, heat control, and manufacturing expertise. When these elements come together, the result is a motor that delivers dependable performance day after day. At CY International Private Limited, we fabricate E-Rickshaw motors that meet these expectations and strengthen trust among our customers. It is what makes us one of the best E Rickshaw motor manufacturers in the market, making us the first priority among E Rickshaw manufacturers and buyers.